Capabilities

Mikrotech is a Full-Service Micro Manufacturer of Custom Components and Subassemblies

As a full-service micro manufacturer, Mikrotech makes custom-designed components and subassemblies used in the Medical, Defense, Optical, and Consumer Goods Industries. We employ best-in-class plastic micro machining and micro molding equipment specifically designed for micro manufacturing. Our processes overcome the limitations of established technologies, facilitating smaller components with more complex features and higher precision tolerances.

Prototyping

Mikrotech offers 3D printing, CNC machining, and Micro Injection molding for prototyping and production.

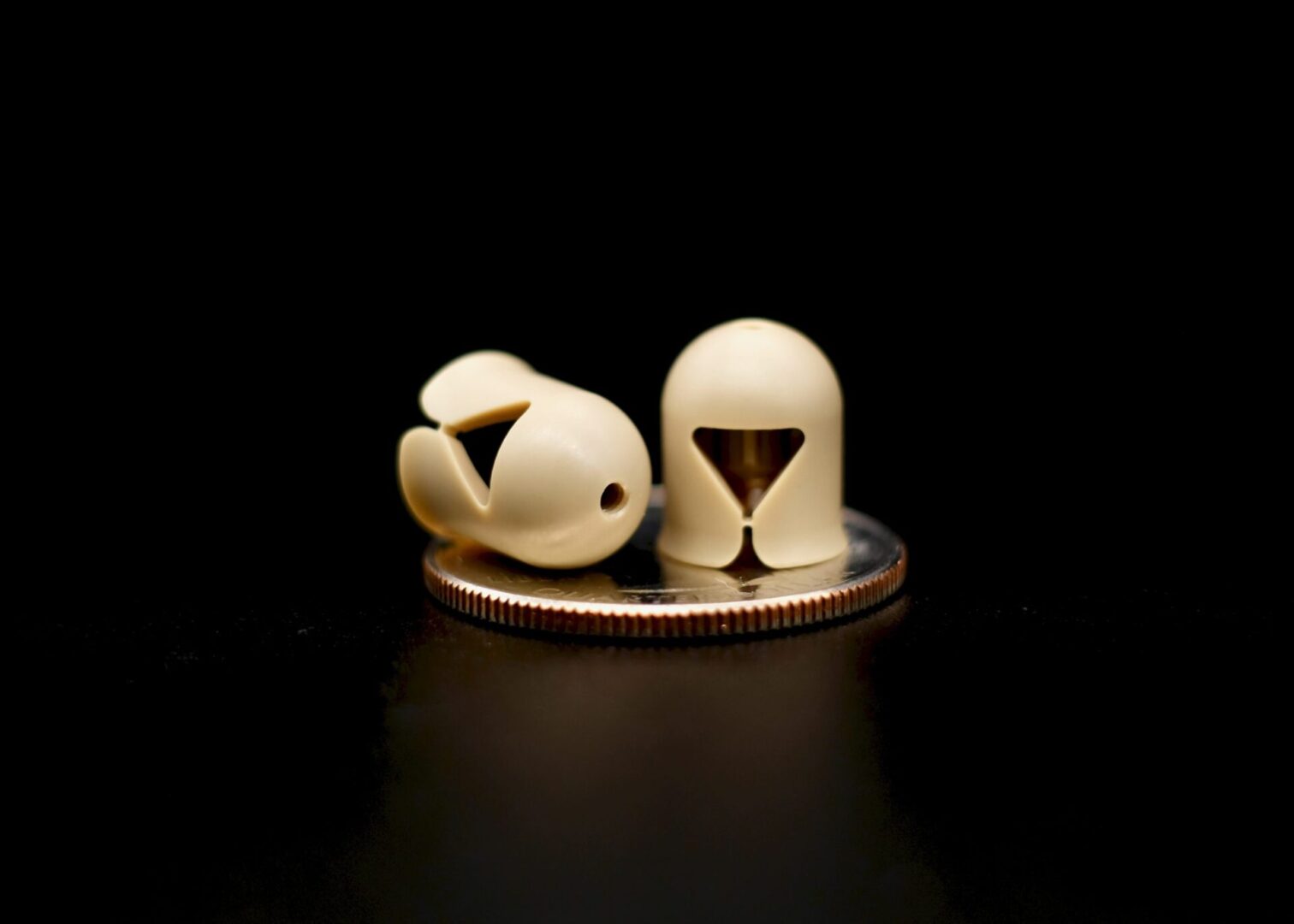

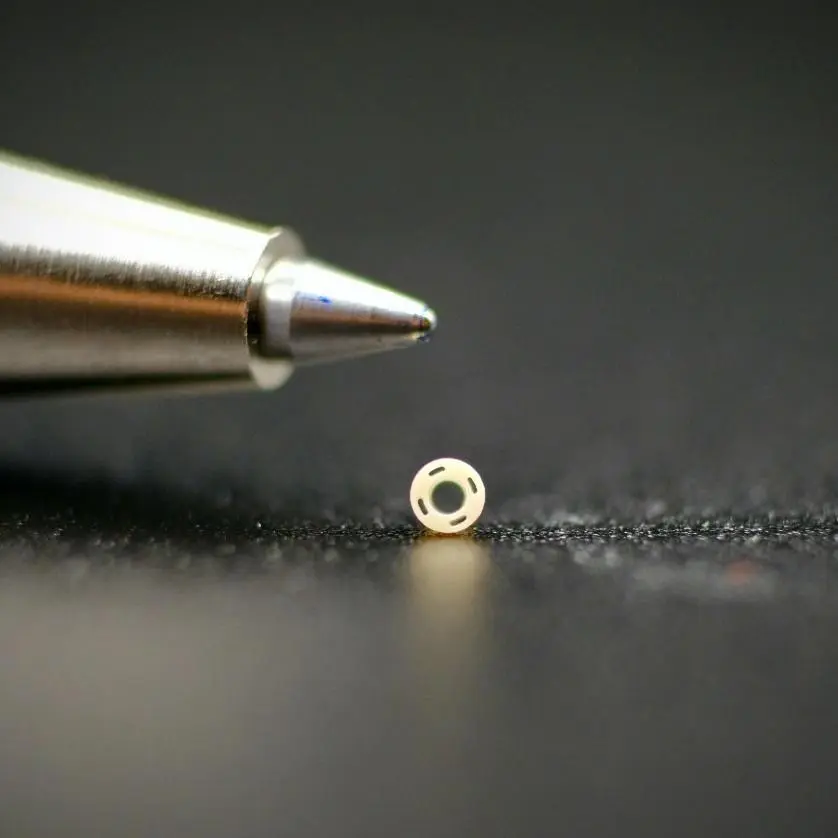

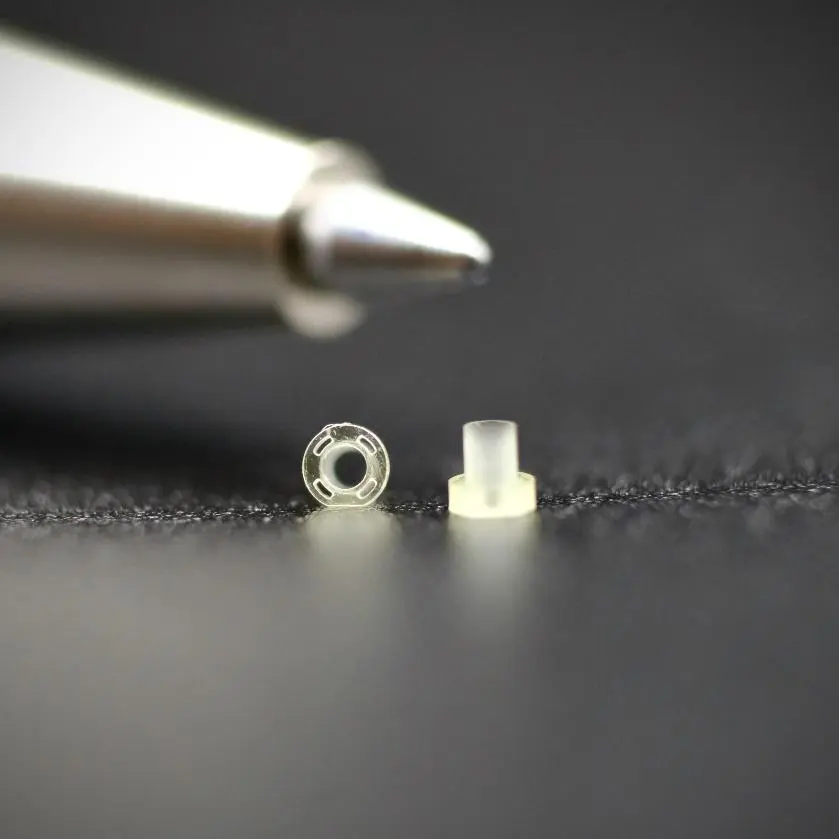

Micro Molding

Micro machining

Our advanced micro-machining services exceed conventional machining constraints, allowing for the creation and production of miniature components with intricate designs and superior precision. We specialize in top-tier multi-axis CNC and Swiss-screw machining for both plastic and metal materials, perfectly suited for prototype development and small-scale manufacturing. This expertise enables us to craft components with enhanced complexity and tighter tolerances, pushing the boundaries of what's possible in precision engineering.

Micro Insert & Over Molding

Insert injection molding is a precise manufacturing process that involves integrating a pre-fabricated component into a mold. Insert and Over molding eliminates the need for some post-molding assembly operations, which can significantly reduce labor costs and production time. These processes consolidate multiple manufacturing steps into a single molding operation, leading to faster production cycles, increased efficiency, and lower in-place costs.

Micro Subassembly

We offer in-house custom automation, through ASYST Automation, for high-volume manufacturing of micro devices.

Manufacturing Engineering Assistance

Our experienced engineering team can provide you with advanced technical, manufacturing, and materials assistance. By carefully considering critical factors, we can optimize your design for both quality and manufacturing. It's crucial to work closely with experienced micro-molding specialists to navigate the unique challenges of this precise manufacturing process. Our design and project management tool box was developed over 20 years and is continuously updated to ensure your success.

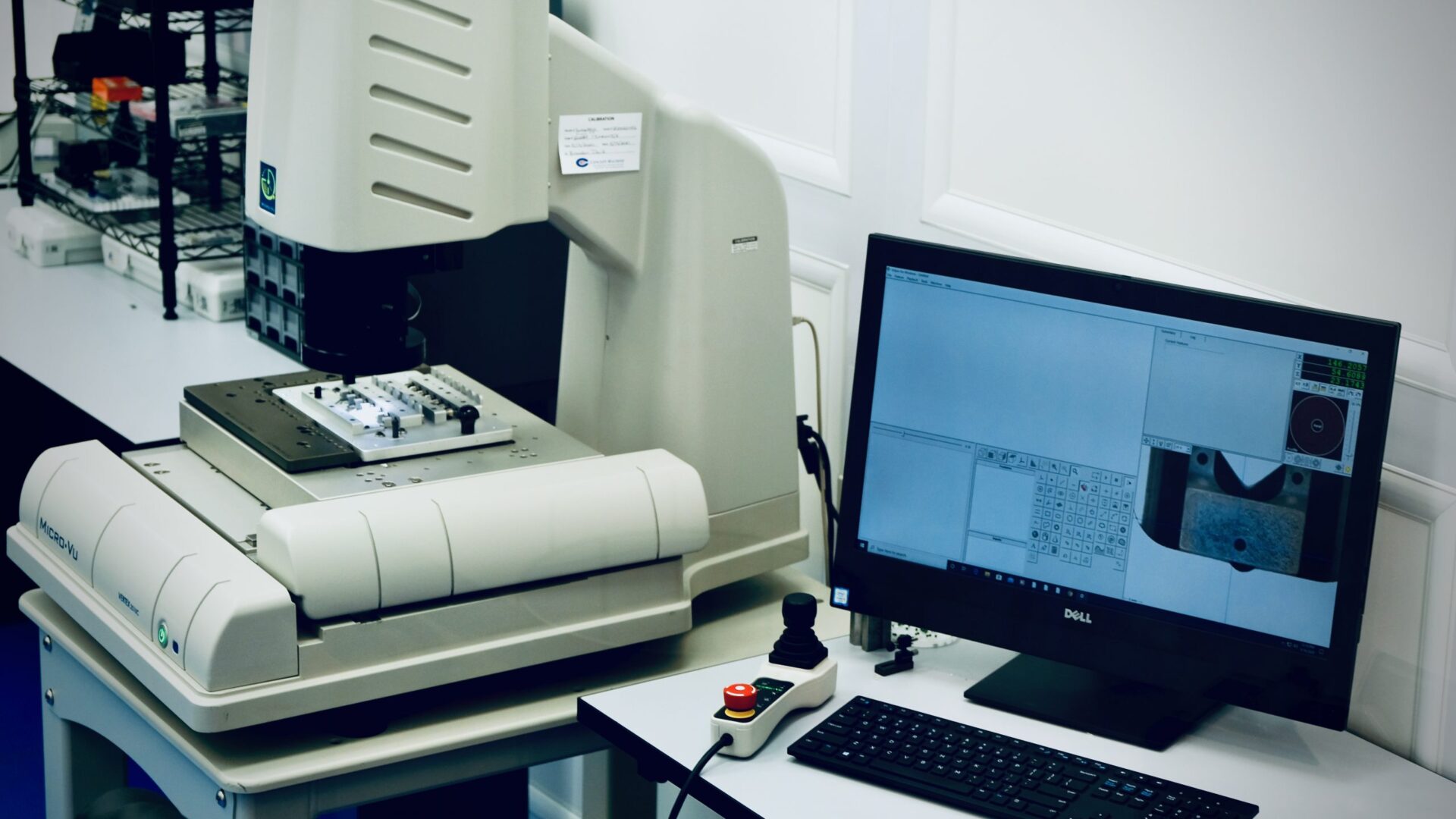

Quality

We are committed to achieving 100% customer satisfaction. Our Quality Management System is ISO registered (13485:2016). Our facility includes an ISO Class 7 Clean Room and state-of-the-art inspection equipment.

Our rigorous quality control measures include comprehensive in-house inspections conducted throughout the molding process, as well as meticulous final audits, ensuring the highest standards of product excellence.

Micro molding provides an excellent, cost-effective solution for micro devices. Mikrotech employs specialized micro molding equipment and tooling that has twice the precision and repeatability as conventional equipment and this allows us to produce high-quality molded components in a variety of different materials.