Quality Control Processes

We do quality as if our lives depended on it – because they do

For us, quality is personal.

Mikrotech is part of a family of six companies which, together, have decades of combined complex engineering experience and the shared knowledge that has informed our quality processes. While we serve a variety of industries, from medical to automotive to defense, our core business from our inception in 1996, has been making micro components used in minimally invasive medical instruments and devices. Like the catheter tipswe manufacture, for instance, that are inserted into a person’s heart for the delivery of medicines through a stent. Or the micro component we make for a leadless pacemaker that serves as part of its delivery and retrieval system that keeps a heart beating in time.

With every micro component we make, we take to heart what Mikrotech President Kevin Brennan instills in us every day:

Whatever the project, whatever the part, approach the job as if what we produce is going to wind up in the heart of a loved one. Because it just might.

We have to get it right every time. Anything less than 100% can literally mean the difference between life and death. Like we said, when it comes to quality standards, we take it very personally.

One of the key measures of exceptional quality is consistency. In making really tiny components, it’s difficult to produce a consistent product. But that’s what we pride ourselves on doing best. We hold ourselves to rigorous standards that are above and beyond what other companies in our field are required to meet. It’s what sets us apart.

Mikrotech adheres to the Advanced Product Quality Planning (APQP) process for manufacturing projects. This quality process is typically applied to the automotive industry, not medical devices. Our ISO requirements do not oblige us to use this quality process but we apply it anyway because it lends to each project a precise structure that ensures we are meeting the highest standards of quality every step of the way.

What is APQP?

The Automotive Industry Action Group, a non-profit trade organization devoted to education and training in the mobility industry, defines Advanced Product Quality Planning (APQP) and Control Plans as “reduc[ing] the complexity of product quality planning for customers and suppliers by allowing customers to easily communicate their industry’s requirements for achieving part approval to their suppliers.” In other words, it’s all about communicating with the utmost precision. The APQP process involves extensive documentation of every step involved in the manufacturing of a component, from start to finish, including a:

- Process Flow Diagram – shows each step in the making of a component from start to finish;

- Process Failure Mode & Effect Analysis (PFMEA) – details the risks involved in each step, what could go wrong, and how to prevent it; and

- Control Plan – outlines in detail each step in the process, and what needs to happen at each step.

Our quality standards

The reason Mikrotech applies the APQP process to every project we undertake evolved from our origins as a division of ASYST, a diversified supplier of custom assemblies and insert molded products for the automotive and medical industries. When Mikrotech spun off as our own LLC, we retained the best practices from the automotive industry’s quality standards. At the time, the medical industry wasn’t using these processes. We started seeing more of a trend in applying automotive quality standards to medical instruments following the economic crash of 2008. As we all remember too well, that downturn hit the automotive industry hard, and many professionals from that industry migrated over to the medical manufacturing and devices industry. Now the standard across many manufacturing sectors, APQP defines the required inputs and outputs of each stage of the product development process.

That we’ve been practicing APQP since our inception has proved to be a competitive advantage.

“Beehive mentality”

All of these quality documents are the domain of our Engineering department, led by Engineering Program Manager Kelli Dimmer. When we initiate a project, Kelli will set up the paperwork, then meet with the team of each department — Quality, Manufacturing and Engineering — to flesh out their part of the project. Without this kind of close collaboration, the project would never get off the ground. At Mikrotech, there are no silos. Alicia Santos, our manufacturing manager, calls this the “beehive mentality” where everyone is working toward a common goal.

“A company like ours where every person cares about the end product, gives us a distinct advantage,” says Andy St. Martin, Mikrotech’s Quality Technician. Andy joined our company in early 2021 after building a career in IT and quality inspection with big companies like General Dynamics Land Systems and Rolls-Royce, maker of highly-efficient integrated power and propulsion solutions for the aerospace and airline industries.

“The most critical thing we do as quality professionals is to ensure that the customer gets what they are paying for,” says Andy. “They give us a blueprint, the materials, and the geometry that goes into building specific dimensions. If it turns out that the finished product is off by even one-thousandth of an inch, it’s a big deal.”

He adds: “Our job is to make sure the end product is perfectly precise .”

Measure, measure, measure

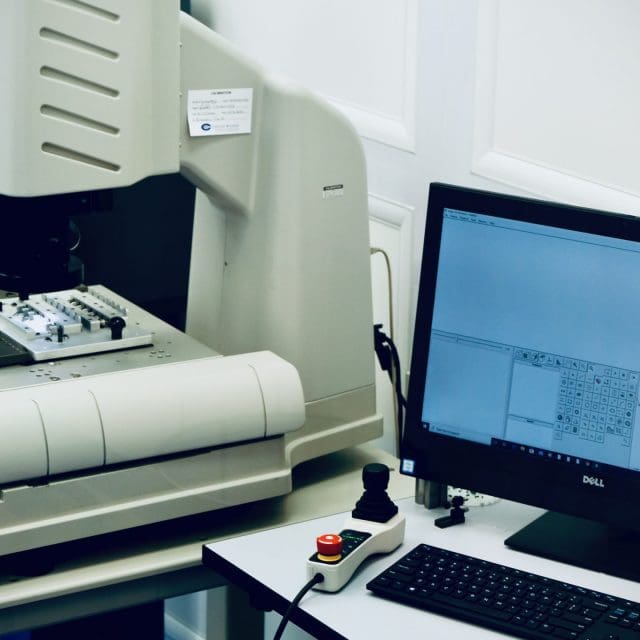

Our rigorous inspection process ensures the micro components we make meet that standard of perfection. Our process employs a specialized programmable camera called the Micro-VU Vertex 25IUC Vision System that can zoom in on an object up to 200 times (compare that to about 10X for a standard smartphone camera) and uses lighting to measure edges and features on the part to determine consistency. The camera is mounted in a fixed position on runners that are calibrated so when the camera moves a certain distance, it is equal to a particular measurement.

“It’s like a microscope on top of a ruler,” Andy explains. Except that, while a standard ruler is marked down to 1/16 of an inch (.0625), our camera is marked down to one/one-millionth of an inch (.000001).

“It’s having these kinds of capable tools that, when used correctly, give us a whole new level of confidence in our precision,”says Andy.

Want to learn more about our Quality Process? Visit our Quality page and then contact us for manufacturing and engineering expertise with your next project.