Micro Insert and Over Molding

Insert micro molding can provide an excellent alternative for the manufacturing of micro devices. Our plastic injection molding equipment is specifically engineered for insert micro molding and has twice the precision and repeatability as conventional molding equipment. This enables us to achieve tolerance targets on complex components that conventional molders cannot maintain; and streamlines the manufacturing process to create a more robust and reliable design for manufacturing.

Insert Micromolding Tip 2

Micro Insert & Over Molding

Over Micromolding Gear

Micro Insert & Over Molding

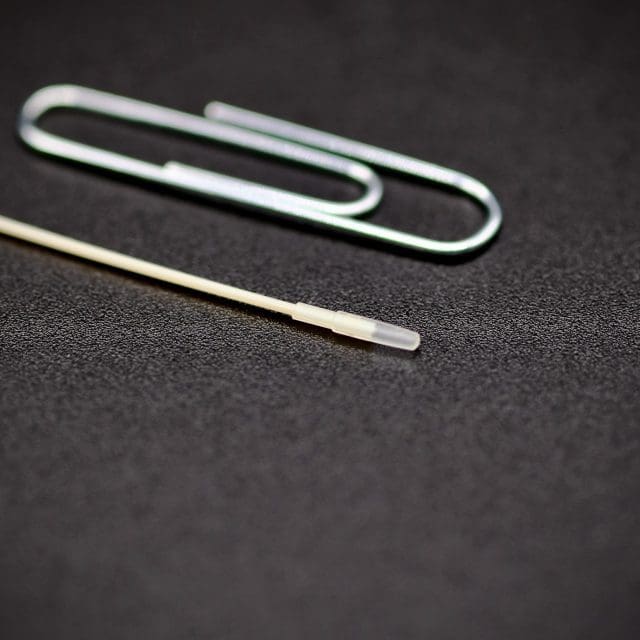

Insert Micromolding Tip 1

Micro Insert & Over Molding

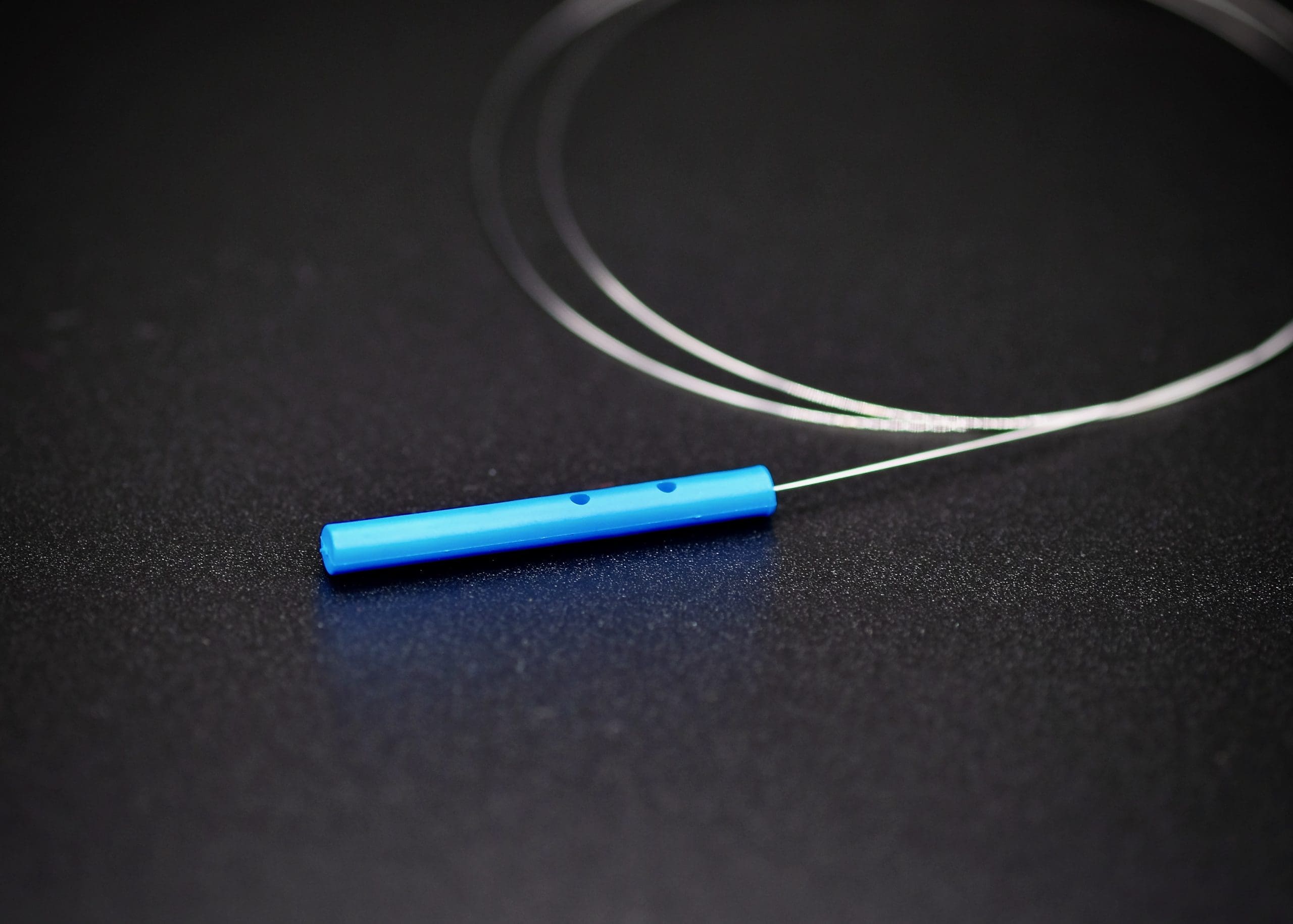

Insert Micromolding Stylet

Micro Insert & Over Molding

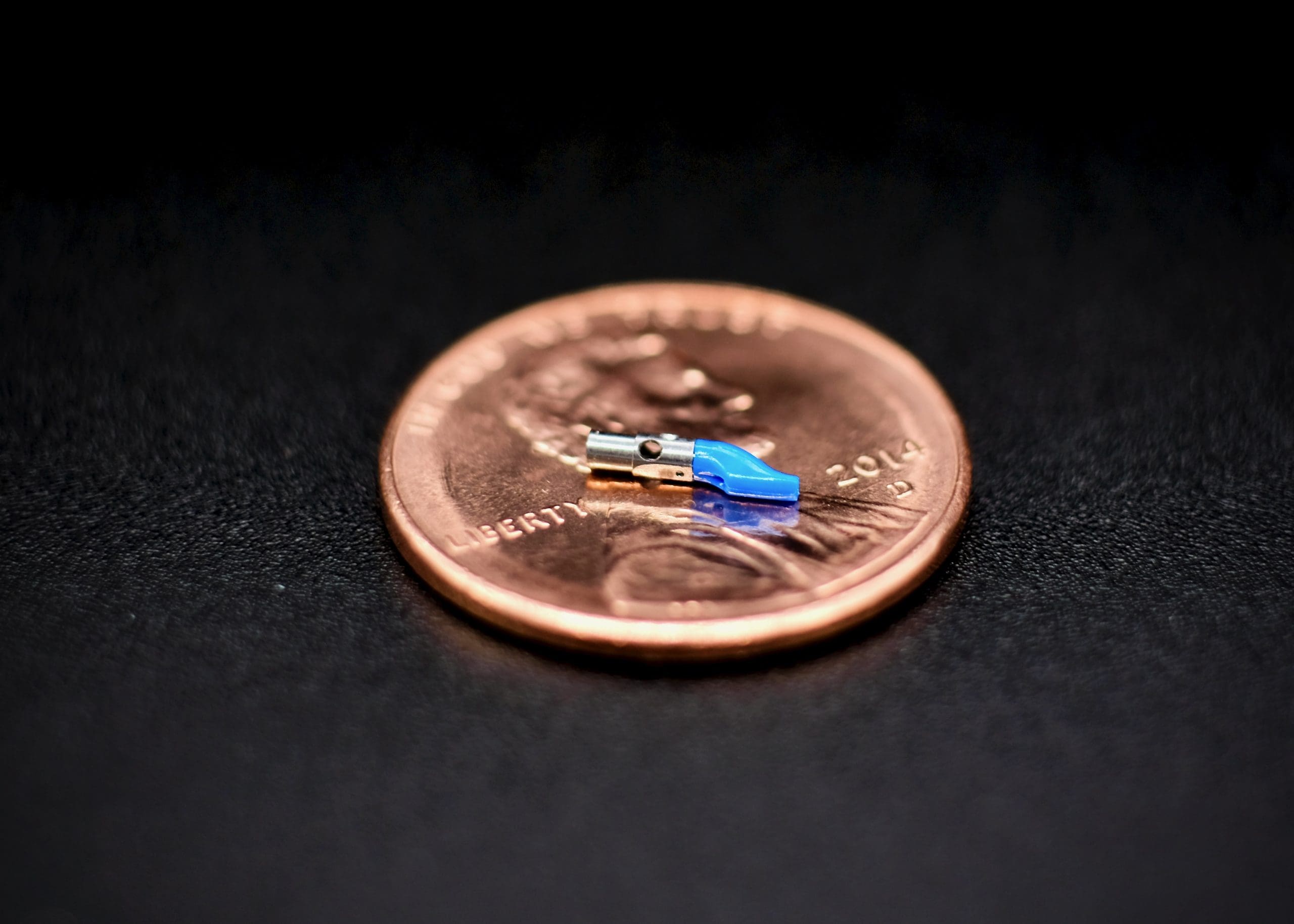

Insert Micromolding Part 1

Micro Insert & Over Molding

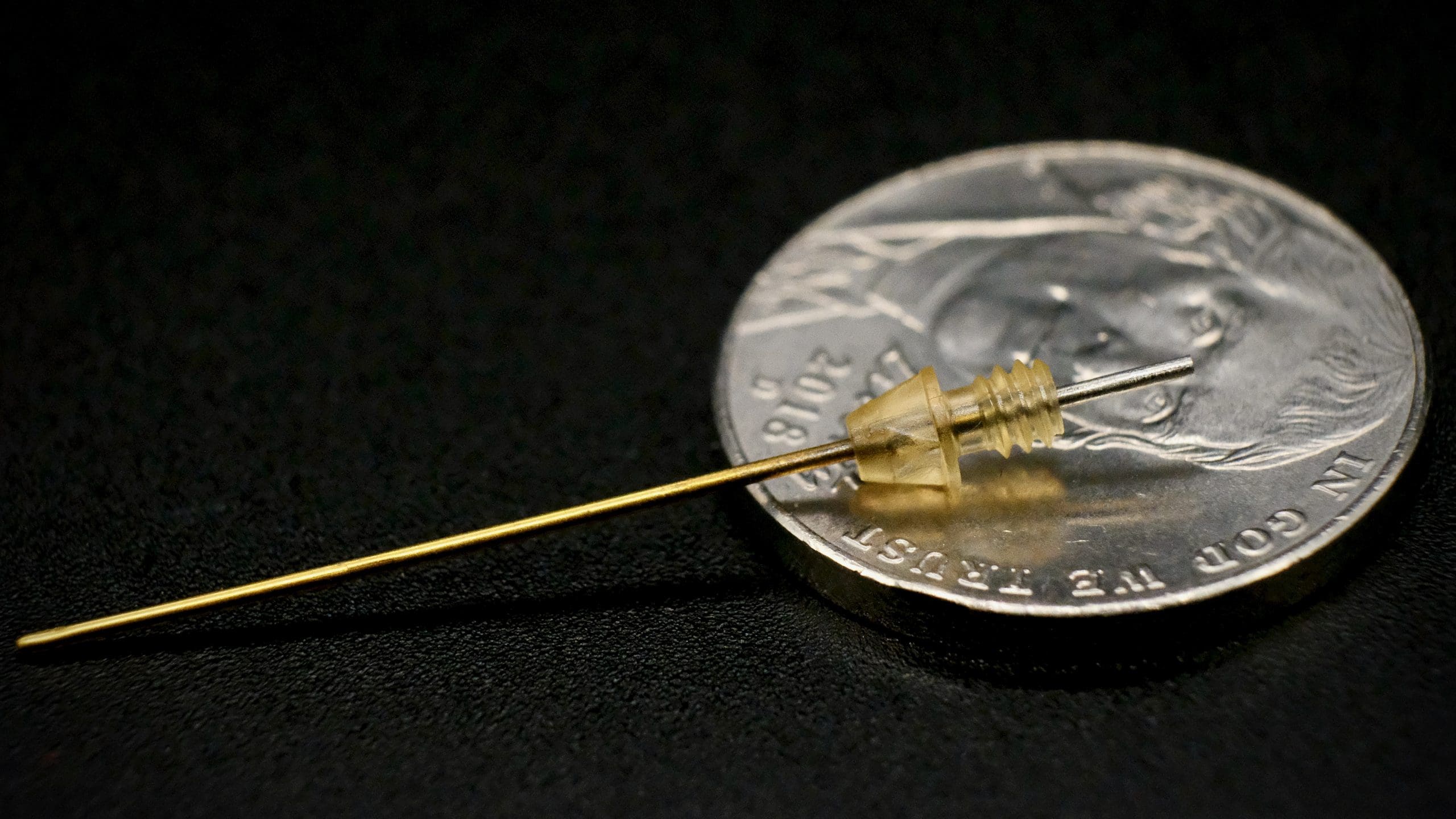

Insert Micromolding Needle

Micro Insert & Over Molding

There are numerous benefits to employing insert micro molding technology in the manufacturing of new and existing work devices. These include:

- Minimal or zero dependency on microscope to assemble

- Elimination of expensive machined components

- Reduction or elimination of secondary operations

- Increased production yields

- Decreased manufacturing cycle time

Micro Insert and Over Molding FAQs

Micro insert and over molding are similar but distinct processes. Micro inserting is a process which molds a separate part, often of another type of material, over an existing part, such as a wire. Over molding entails molding one part and then molding a second part over it.

Our plastic injection molding equipment is specifically engineered for insert micro molding and has twice the precision and repeatability as conventional molding equipment. This enables us to achieve tolerance targets on complex components that conventional molders cannot maintain; and streamlines the manufacturing process to create a more robust and reliable design for manufacturing.

We employ both manual and automated insert molding, and typically work with lumens, wires, marker bands, and needles. To mold over an object such as a needle, for instance, our operator will load the object into a mold tool by hand. In our automated process, we use end-of-arm tooling designed for the object to load into the mold.